In late 2024 the fountain pen community was shaken by the news of the sudden passing of Greg Hardy, the well-loved character behind Hardy Penwrights. But Hardy Penwrights lives on, in the hands of Greg Hardy’s son Gavin.

Gavin started working for his father after moving back from Wisconsin to northern New York, to be nearer family. “My parents were selling my childhood home so we bought it and renovated it.” Because Greg wanted to expand the business, Gavin, otherwise a fulltime musician, began working for Hardy Penwrights.

“When I was a kid, he had given me a fountain pen, you know, the plastic Sheaffer with the flat top…” (probably a Sheaffer No Nonsense) “…so I was interested in them. Senior year I needed an extra elective so I put together a calligraphy class with my dad.”

Pens took a back seat to music until Gavin returned to New York. “I never made a kit pen. My dad gave me detailed instructions on how to turn a pen, and I learned.” The shop was at Greg’s house, about a twenty minute drive in the morning. “We’d drink coffee for an hour and a half and then start our work.” Ultimately most of the shop was relocated to Gavin’s house. “He wanted to do less of the business and more metal work, which he was more interested in.”

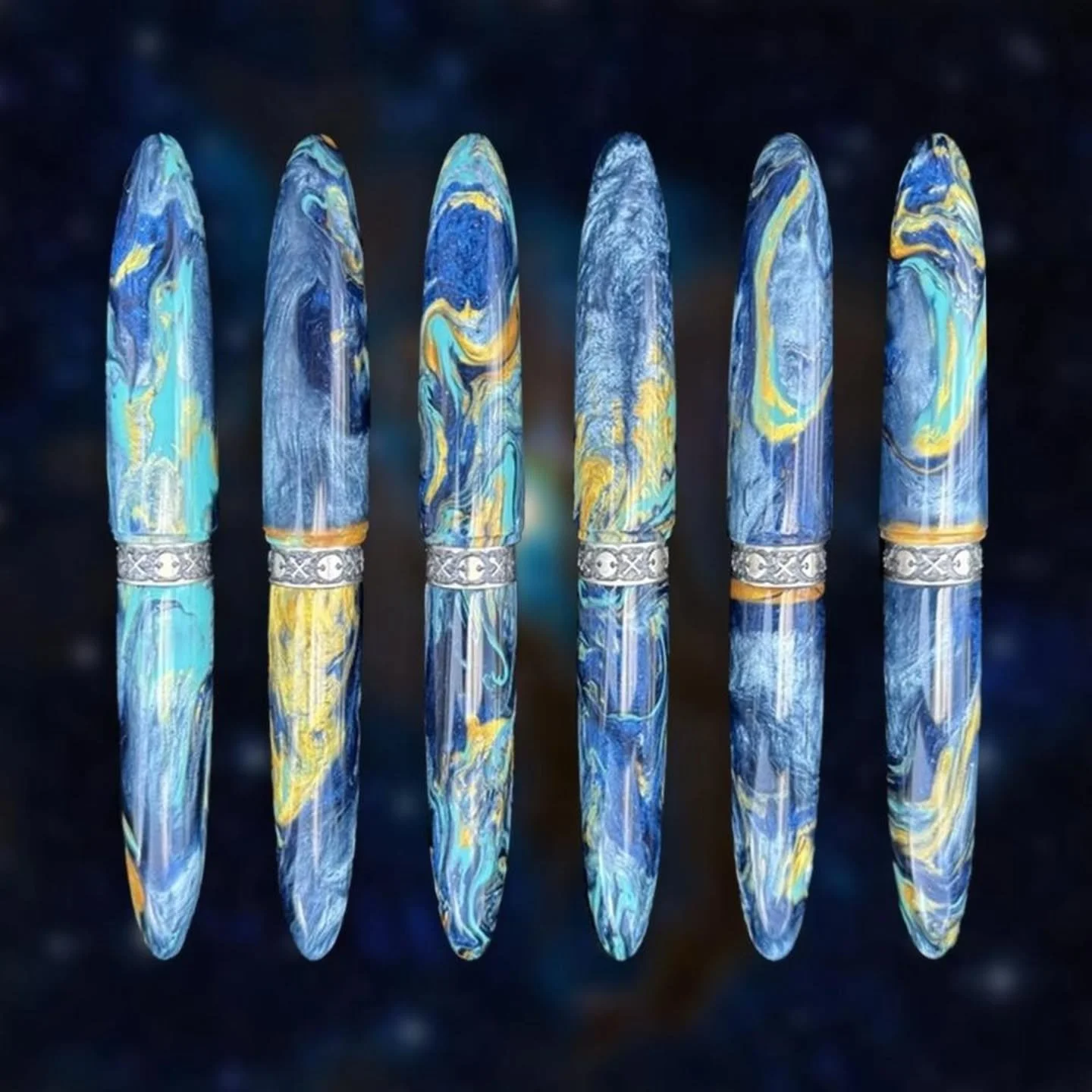

“He gave me a crash course in soldering techniques - we did a few runs of pens where I did the clips. I wanted to make sure we were still able to offer the metal work. It was certainly educational!” Education also came from Tim Crowe of Turnt Pen Company, who lived not far away and is a blank casting specialist. “Tim gave me the setup to get started – a pressure pot, a compressor, a mold, some mica. There is more instant gratification in material casting than on the pen side.”

How does one step out from the shadow of one’s well-known parent after inheriting a thriving business? Gavin says Greg’s primary focus was “creating art. I think that’s noble and beautiful and I want to do that too, but I’m not retired!” He’s working on making some changes to the company’s lineup, to make products that are viable for shows. “I wanted a less expensive model that’s just as nice as our other models.”

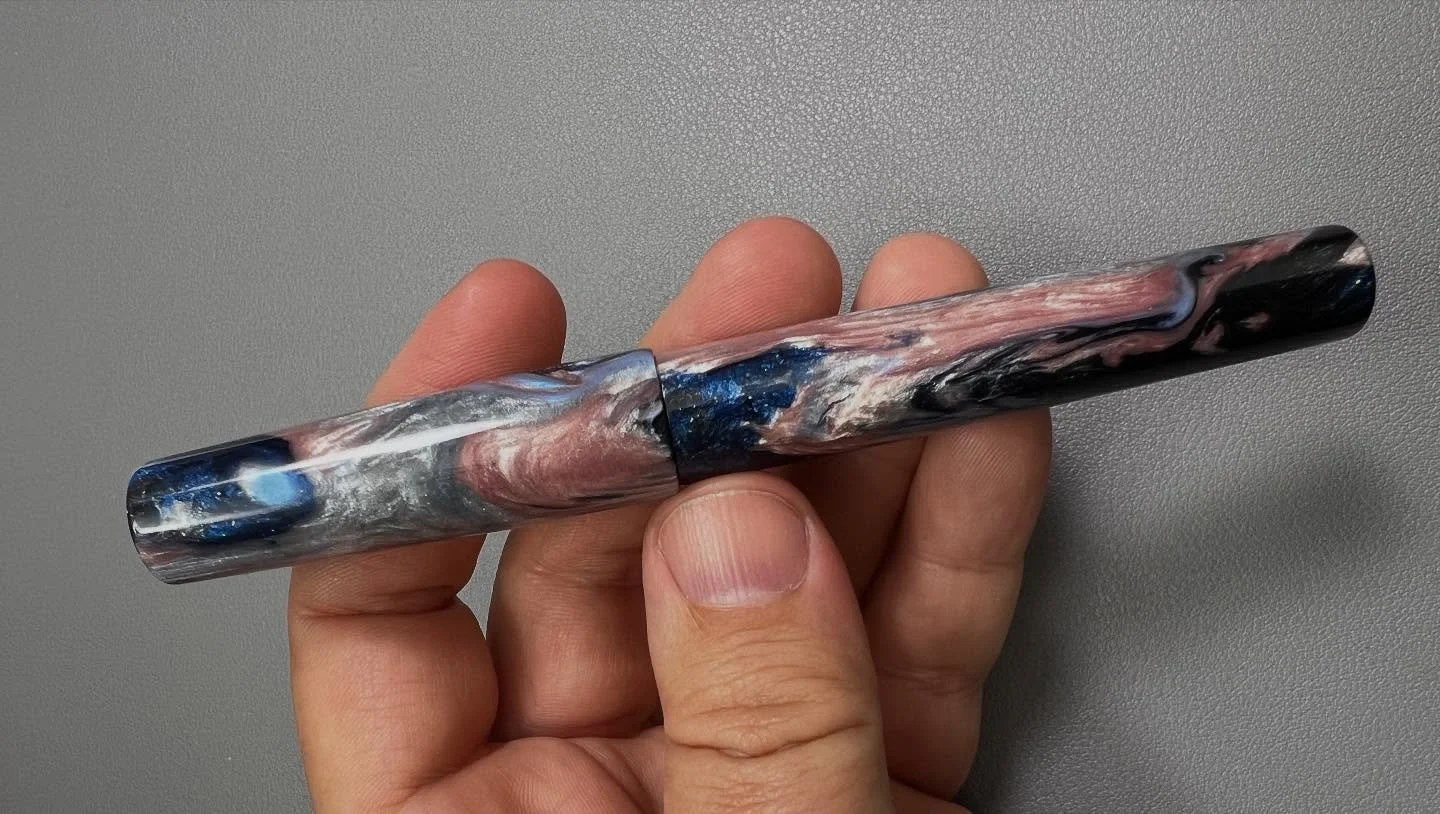

The first result of this process is the Proletariat model. The pen has a satin finish instead of a glossy polish, and a laser engraved logo instead of cast silver. The sections are made from cutoffs from other projects. “I’m focusing on the Proletariat as our main production model, and simplifying what we do across the lineup. The goal is the same as it was, to produce a quality fountain pen that makes people want to use it.” Gavin is still making clips – “Maybe we’ll have one signature clip instead of a different one for every model, and vary that for a custom or limited run. I’m making it easier for one guy in a shop to keep up.”

There have already been a couple of custom pieces that have tested his mastery of the metalwork that was his father’s passion. A pen for a close family friend and neighbor has a rollstop with special significance. “She wanted something that was representative of our family, so the roll-stop had two big circles representing me and my wife in silver and bronze, and two little circles representing our kids in mokume gane which has silver and bronze swirled together.” A custom pen with a complex cap overlay of birds and leaves represents a continuation of the Hardy metal tradition.

Despite the ability to make such complex pieces, Gavin’s favorite pens that didn’t come out of the Hardy workshop are in a different style. “I have a really cool PapaJ pen. I gave him some ideas when he wanted to make rollstops, and he sent me one with his floral rollstop.” He does have one of his own making – “it’s black, it’s boring” – and then he likes “Zebra clicky pens! I like the slim fine ones.”

Things are still settling out with the business, website, and show schedules. It’s taking some time to get the business fully transferred to his name, and updating the website is a pending task. He only envisions attending two shows in 2026, and maybe adding one or two more next year. “My goal is three to six shows a year. I just can’t keep up the schedule my dad had.”

Even doing it all on his own now, he still enjoys the work. “There are things I don’t enjoy, but that’s any job. When I’m doing a run of thirty pens, that gets a little hairy, but I enjoy audiobooks and podcasts.” Unlike many makers, this musician doesn’t listen to music in the shop. “I find myself thinking about the music too much.” DND live-play podcasts are more his speed.

Gavin has no trouble articulating what he likes best about making pens. “There’s a sense of accomplishment and pride in seeing other people’s reactions to something you made. There’s the community it hooks you up with – people who are interesting, kind, and supportive. And there’s the flexibility of working for myself – I have a four year old, a two year old, and a wife with a demanding job.”

The legacy of Hardy Penwrights also provides a deep sense of meaning. “I’m continuing what I was doing with my dad, keeping that part of our relationship alive. And it’s possibly something I can also share with my kids.”

Gavin Hardy’s work can be seen on his Instagram @hardypenwrights, the website at Hardy Penwrights, and at shows in Chicago and DC.

Enjoy reading The Pen Addict? Then consider becoming a member to receive additional weekly content, giveaways, and discounts in The Pen Addict shop. Plus, you support me and the site directly, for which I am very grateful.

Membership starts at just $5/month, with a discounted annual option available. To find out more about membership click here and join us!